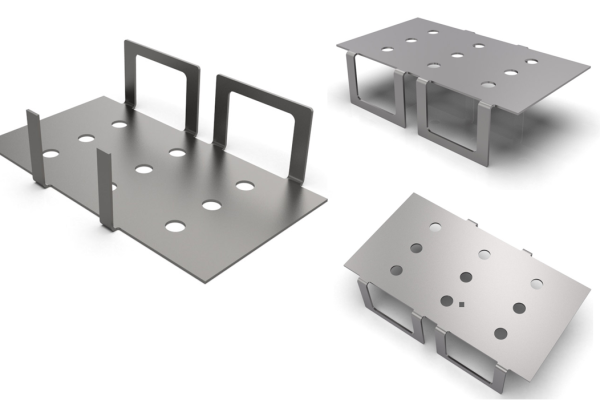

Advantages of Sheet Metal Fabrication

OYA is an experienced provider of Sheet Metal Fabrication services with lots to offer beyond our competitors:

1. Material selection

Aluminum + , copper, stainless steel + , steel and zinc

2. Finishing options

Bead blasting, anodizing, plating, powder coating and custom finishes

3. Thickness options

Variety of gauges available

4. Durability

Sheet metal fabrication produces durable parts for prototyping or end use

5. Scalability

Low setup costs mean low prices for large volumes

6. Turnaround

Parts delivered in just 5-10 days