Injection Molding Services

OYA provides low-volume and mass production injection molding services.

- Thermoplastic

- Thermoset Silicone

- Metals

Custom injection Molding Parts

Whether you require low-volume injection molded parts or large quantities of end-use production moldings, our injection molding services are the perfect choice. At OYA, we specialize in producing high-quality prototype moldings using rapid tooling made from aluminum or soft steel, with remarkably quick turnaround times as short as 7 days. This allows our customers to efficiently validate their designs for manufacturability, functionality, and swiftly test the market. Additionally, we provide plastic and metal production moldings to cater to your high-volume production requirements. With our team of experienced specialists, we guarantee a cost-effective solution at every stage of the process.

High Quality

Our Injection Molding

Capabilities

We are well-prepared to tackle the challenges associated with a wide range of injection molding parts, including tight tolerances, thin walls, small draft angles, undercuts, complex part geometries, and demanding surface finishes. Our expertise and capabilities ensure that we consistently deliver exceptional results for even the most complex projects.

Plastic Injection Molding Service

Thermoplastic injection molding is widely regarded as the preferred choice for custom plastic parts. This versatile process is highly suitable for a variety of industries, including consumer products, automotive components, and numerous other applications. Its popularity stems from its ability to deliver high-quality, precise, and cost-effective solutions.

Liquid Silicone Rubber Molding Service

Liquid silicone rubber, known for its inertness and biocompatibility, is a highly suitable material for molding medical items. It finds extensive use in fluid management and respiratory devices, among other applications within the medical industry. Its unique properties make it an ideal choice for manufacturing high-quality and safe medical components.

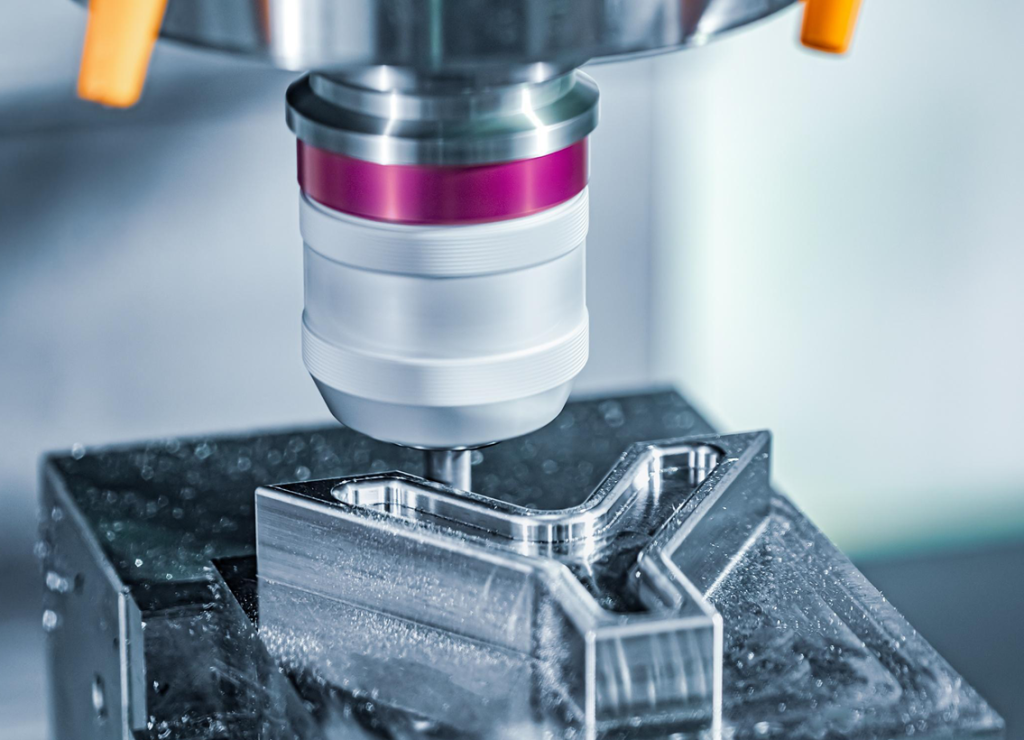

Metal Injection Molding Service

Metal Injection Molding (MIM) is a cost-effective solution for producing small and intricate metal parts. It offers significant advantages, particularly in large volume production, as it minimizes material waste compared to CNC machining. MIM's ability to efficiently manufacture complex geometries makes it an excellent choice for achieving high precision and intricate details in metal parts.

30t-1800t

INJECTION MOLDING

MACHINES

1 PC

NO

MOQ

10K+

NJECTION MOLDINGS

MADE MONTHLY

100+

PLASTIC &

METAL MATERIALS

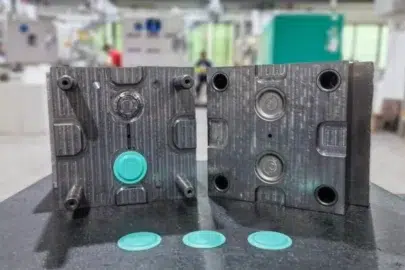

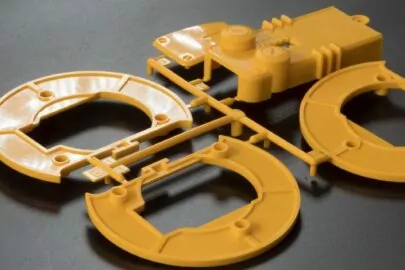

Injection Molding Gallery

To showcase our injection molding capabilities, here are a few examples of our past projects. At OYA, we possess the flexibility and expertise to handle a wide range of high-quality injection molded parts. When it comes to mold making and injection molding services, we are your one-stop solution. Look no further; we have everything you need for your projects.

We Love What We Do

Why Choose Us

Prototype and Production Moldings Made Easy

Get 7-day standard lead times on simple parts between 0.5 in. x 0.5 in. and 4 in. x 3 in.

Upload your part to see if it’s eligible.

1

Upload CAD file

2

Quote & Design Analysis

3

Order Confirmation

4

Parts Shippep

Addition Injection Molding Options

Besides basic injection molding services, we also offer two variants of the process - overmolding and insert molding. Both of these can be useful in specific situations.

Overmolding

Overmolding uses injection molding to create a part from multiple materials. This process adds an injection-molded layer of material over an existing injection-molded workpiece. The overmolding process produces chemically bonded parts made using various materials.

The overmolding method is often cheaper and more effective than other manufacturing approaches that require creating and assembling component material parts separately. The process can also build layered parts from scratch or add a resistant outer layer to existing plastic parts and tools, providing a rugged exterior. Toothbrushes consisting of a solid plastic body and rubberized grip are an example of an overmolded product.

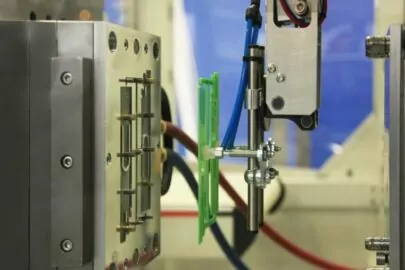

Insert Molding

It is similar to overmolding, but the substrate is not necessarily plastic and does not have to be produced via injection molding. For example, it can be used to add a plastic coating to a pre-fabricated metal part.

Common parts made with insert molding include sharp handheld tools, such as scalpels that consist of a metal blade partially housed within a plastic handle. This manufacturing process is also frequently used to create inserts incorporating bushings, clips, and fasteners.

From Prototyping to Mass Production

OYA offers one-stop manufacturing solutions. Whatever your need rapid tooling for prototype molding or production tooling for mass production parts.

Prototyping & Low-Volume Production

The prototype molds are normally made as single mold cavity in aluminum or P20 steel. With hand-loaded inserts to avoid using cylinders and lifters. Standard stock mold base is another fact to lower the mold cost. It is the best way to get a few prototypes in real materials for testing, or to create a few hundreds and thousands of bridge production parts in a very short lead times.

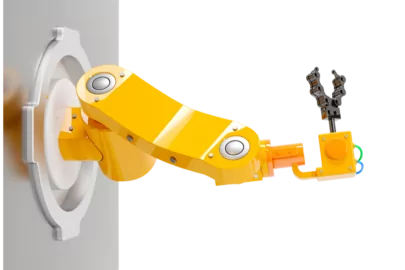

Mass Production

When you are ready for million+ of mass production moldings, it is important to keep the injection molding cost as low as possible. That’s why production injection mold tools are made as multi cavities to reduce the cycle time, and fully hardened tool steel to ensure the tool life. In the meantime, robots are widely used to cover the labor cost.

Mold Tooling and Molding Materials

Wide range type of industrial-grade materials can be used for mold tools and moldings, giving you lots of material selection options to complete prototypes and production runs. Tooling materials such as aluminum and steel, and molding material in common plastics such as ABS, PC, PP, PA or temperature resistance plastics like PEI, PPS, etc.

Put your parts into production today

Injection Molding Materials, Surface Finishes and More

Mold Tooling and Molding Materials

Wide range type of industrial-grade materials can be used for mold tools and moldings, giving you lots of material selection options to complete prototypes and production runs. Tooling materials such as aluminum and steel, and molding material in common plastics such as ABS, PC, PP, PA or temperature resistance plastics like PEI, PPS, etc.

Surface Finishes

OYA offers wide variety high level surface finishes. We only list some of the common finishing options. There are more finish options for custom injection molded parts.

Classes of Injection Mold

We adhere to the five standard categories of SPI mold classifications from Class 1 to 5, aligning expectations for customers and suppliers alike.

Discover More About Injection Molding

Here we present some further information about injection molding, such as what is injection molding, steps to get injection molded parts, what are the 4 stages of injection molding process, the advantages compared to other manufacturing processes such as CNC machining, 3D printing, laser cutting.

VERSIONS HAVE EVOLVED OVER THE YEARS

Injection Molding Applications

Injection Molding FAQ's

The first step in our injection molding service is to design the injection mold tool. How long this takes will depend on the complexity of your project. The usual timeline can be as short as a week and as long as a couple of months.

The plastic pellets are melted and then inserted in liquid form into the mold tool, where it cools and takes the required shape. The process allows for high precision and tight tolerances because it can be replicated exactly each time.

Injection molding can use almost any type of plastic that can also be combined together. This unmatched versatility makes injection molding so popular and suitable for some of the most demanding industries in the world. You can check out the selection of available materials and finishes our injection molding service handles on this page.

Injection molding is one of the most affordable ways to manufacture large quantities of parts, especially for bigger production runs. Even though design for manufacturing and creating the mold can take time, the process then becomes very affordable and efficient.

OUR ARTICLES

There are many variations of passages of lorem ipsum

The Fundamentals of Plastic Extrusion: Process, Materials, and Applications

Plastic extrusion is a widely used manufacturing process for shaping plastics,...

How does sheet metal fabrication work?

Because thin sheets of metal are more malleable than a thick workpiece, they c...