Injection molding and CNC machining are two widely used manufacturing processes that shape materials into desired forms. While both processes involve shaping material, they differ significantly in their approach, capabilities, and applications. This article provides a comprehensive comparison of injection molding and CNC machining, highlighting their key differences, advantages, disadvantages, and suitability for various manufacturing scenarios.

Injection Molding

Injection molding is a manufacturing process that produces parts by injecting molten material into a mold cavity. The process involves several steps:

- Mold Design: A custom mold is designed based on the desired part’s shape and features.

- Material Preparation: The chosen material, typically a thermoplastic or thermosetting plastic, is heated until it becomes molten.

- Injection: The molten material is injected into the mold cavity under high pressure.

- Cooling: The material cools and solidifies within the mold, taking the shape of the cavity.

- Ejection: The solidified part is ejected from the mold.

Advantages of Injection Molding

- High Production Rates: Injection molding excels in high-volume production, allowing for the rapid manufacturing of large quantities of parts.

- Complex Part Production: Injection molding can produce parts with intricate geometries and internal features, making it suitable for complex designs.

- Consistency and Repeatability: The process ensures consistent part quality and repeatability, critical for mass production.

- Material Efficiency: Excess material can often be recycled, minimizing material waste and promoting sustainability.

Disadvantages of Injection Molding

- High Initial Investment: The upfront cost of designing and creating molds can be substantial, especially for complex parts.

- Limited Material Choice: Injection molding is primarily suitable for plastics and certain elastomers, limiting its application with other materials.

- Longer Lead Times for Mold Creation: Mold design and fabrication can extend the overall production timeline compared to CNC machining.

- Design Restrictions: Certain design constraints exist, such as the need for uniform wall thickness to prevent defects.

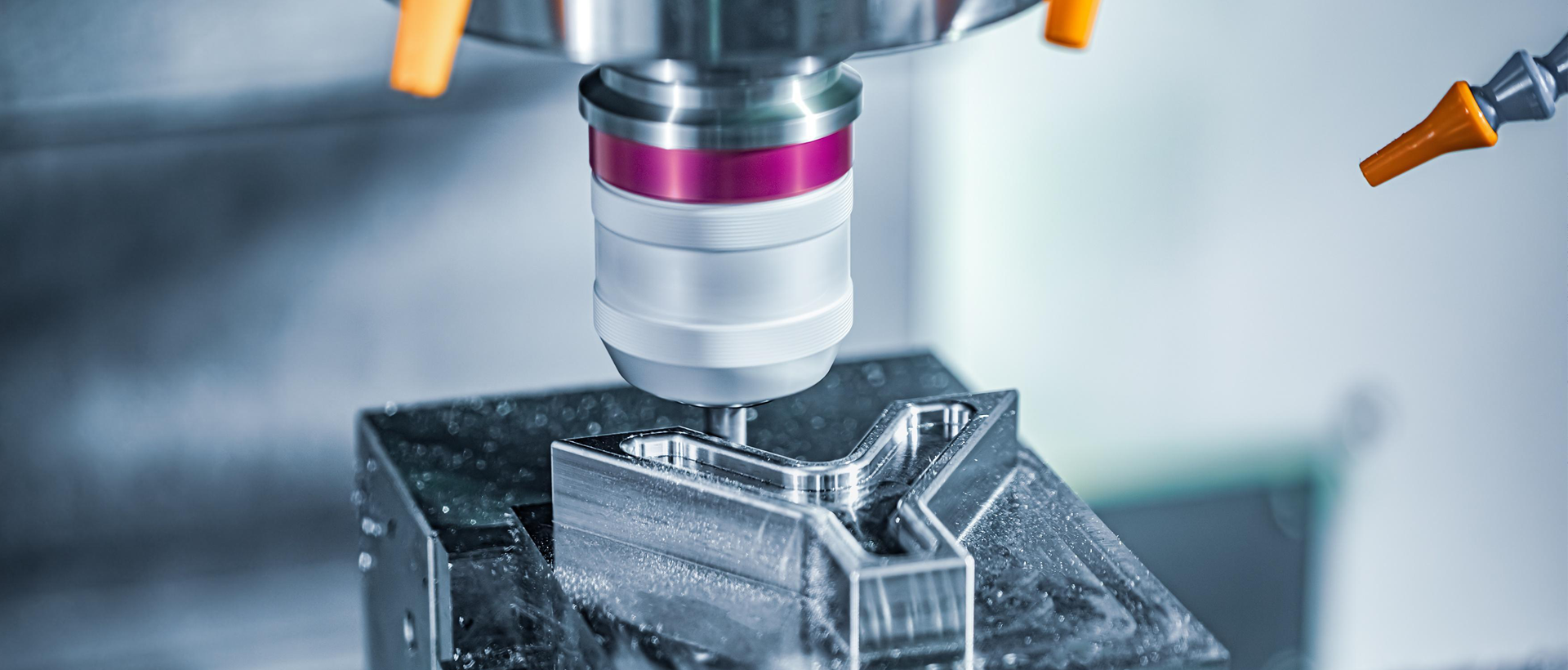

CNC Machining

CNC machining, also known as computer numerical control machining, is a subtractive manufacturing process that involves the use of computer-controlled machinery to remove material from a workpiece. The process follows these steps:

- Design: A CAD (Computer-Aided Design) model of the desired part is created.

- Programming: The CAD model is translated into CNC code (G-code) that guides the machine’s movements.

- Setup: The CNC machine is set up with the appropriate cutting tools and workpiece.

- Machining: The machine executes the G-code, cutting and shaping the workpiece to achieve the desired form.

- Finishing: Post-processing steps may be required to achieve the desired surface finish.

Advantages of CNC Machining

- Precision and Customization: CNC machining offers high precision and the ability to produce parts with complex geometries and tight tolerances.

- Material Versatility: CNC machining can handle a wide range of materials, including metals, plastics, and composites.

- Design Flexibility: Design changes can be made relatively easily, providing flexibility in product development.

- Rapid Prototyping: CNC machining is well-suited for prototyping, enabling the quick production of high-quality prototypes.

Disadvantages of CNC Machining

- Slower Production Rates: Compared to injection molding, CNC machining has slower production rates, especially for large volumes.

- Higher Material Waste: The subtractive nature of CNC machining generates more material waste compared to injection molding.

- Higher Cost for Complex Parts: Complex parts may require specialized tooling and longer machining times, increasing production costs.

- Limited Internal Feature Production: CNC machining may face limitations in creating intricate internal features due to tool access constraints.

Comparison of Injection Molding and CNC Machining

To further understand the differences between injection molding and CNC machining, a detailed comparison is provided across various factors:

| Factor | Injection Molding | CNC Machining |

|---|---|---|

| Process Type | Additive (material is added) | Subtractive (material is removed) |

| Material Suitability | Primarily plastics, some elastomers | Metals, plastics, composites, wood |

| Production Volume | High-volume production | Low to medium-volume production, prototyping |

| Part Complexity | Can produce complex shapes | Can produce complex external geometries, limited internal features |

| Design Flexibility | Limited after mold creation | Relatively high, design changes are easier |

| Production Speed | Fast cycle times for high volumes | Slower production rates |

| Cost-effectiveness | Cost-effective for high volumes | Higher cost per part, especially for complex designs |

| Tooling Requirements | Custom molds required | Cutting tools, less specialized tooling |

Beyond the factors discussed above, several other considerations can influence the choice between injection molding and CNC machining:

Volume and Scale of Production:

- Injection molding is ideal for high-volume production, where the cost per part decreases significantly with increasing volume.

- CNC machining is better suited for low to medium-volume production or when design flexibility is crucial.

Design Complexity:

- Injection molding excels in producing parts with complex internal features and consistent geometries.

- CNC machining offers greater flexibility for intricate external geometries and customized designs.

Lead Time and Speed:

- Injection molding typically has longer lead times due to mold creation but offers fast production speeds once the molds are ready.

- CNC machining has shorter lead times but slower production rates, especially for complex parts.

Cost-effectiveness:

- Injection molding becomes cost-effective for large production volumes due to lower per-part costs.

- CNC machining has a higher cost per part, particularly for small batches or complex designs.

Environmental Impact:

- Injection molding generates less material waste as excess material can often be recycled.

- CNC machining produces more waste due to its subtractive nature, although recycling initiatives can mitigate this impact.

Safety Considerations:

- Injection molding involves high temperatures and pressure, requiring safety measures to prevent accidents.

- CNC machining poses risks from cutting tools and high-speed machinery, necessitating strict safety protocols.