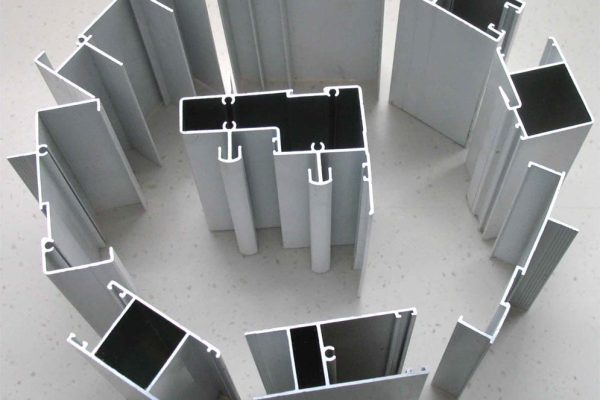

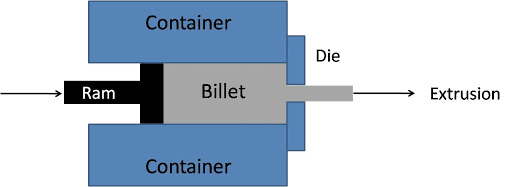

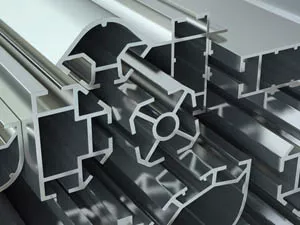

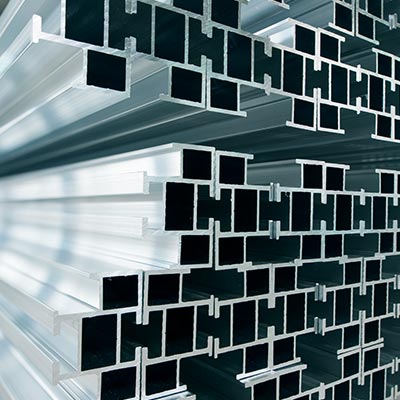

About Our Aluminum Extrusion Capabilities

Gensun specializes in extruding a wide range of standard and custom profiles. Our capabilities include:

- Utilizing alloys like 6061, 6063, and other 6xxx series alloys

- Solid profiles crafted from 2xxx and 7xxx alloys

- CNC machining services for precise finishing of extruded profiles

- Secondary operations such as cutting, drilling, and more

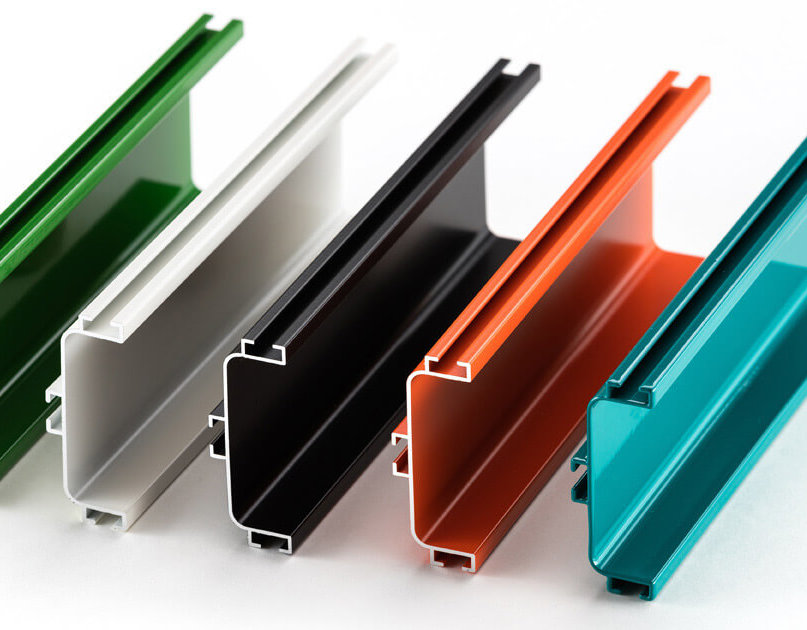

- Comprehensive finishing services including anodizing, painting, powder coating, and beyond

To inquire about our services, discuss the manufacturability of your design, or request a quote, please contact us. We are eager to assist you.