On-demand Custom CNC Machining Services

Online CNC machining service for rapid prototypes and production parts in metals or plastics. Get instant quotes today, and order your custom CNC machined parts at a better price.

- One-off CNC Prototypes

- 100K+ Mass Production Machining

- Tolerance as tight as ±0.005 mm

- Delivery in as little as 5 days

Your reliable partner OYA Precision Machining

Seeking a reliable and efficient CNC machining supplier? Look no further than OYA. With our expertise in custom metal and plastic machining, we possess two state-of-the-art CNC machining factories dedicated to rapid prototyping and production part machining. we offer limitless manufacturing capacity. Rest assured, your high-quality machined parts will be delivered on time, every time. Experience our professional online CNC machining services today!

High Quality

Our CNC Machining

Capabilities

We are always ready for the challenges of tight tolerances and complex CNC machined parts. Try out our precision CNC machining services and become our next satisfied customer.

1.

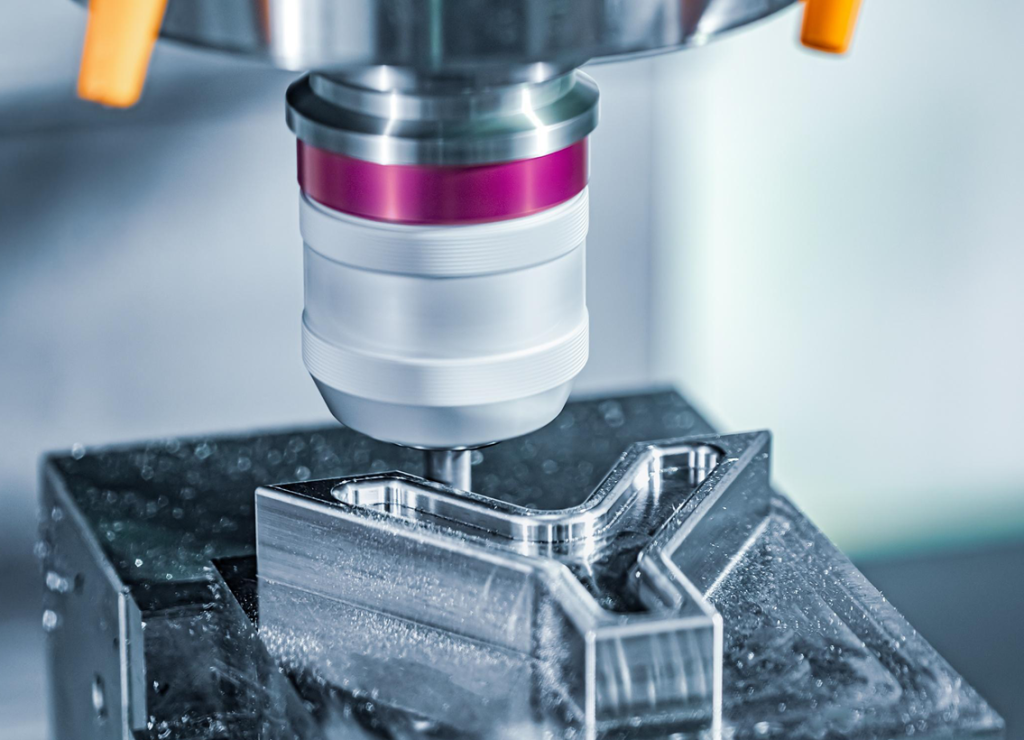

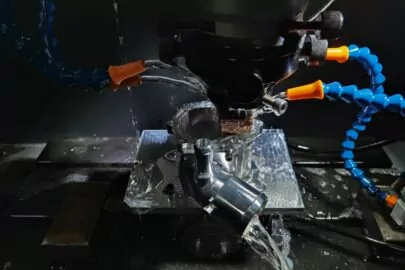

CNC Milling Service

We have a total of 32 sets of 5-axis CNC milling machines in our facility, enabling us to effortlessly mill plastic and metal parts with intricate geometries while maintaining tight tolerances. Additionally, we provide cost-effective solutions by utilizing our 3-axis and 4-axis milling machines for the production of machined parts.

2.

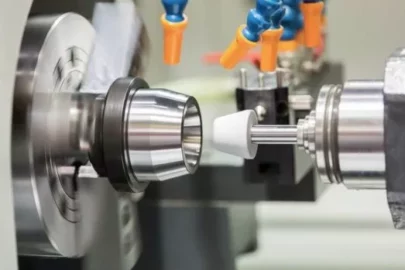

CNC Turning Service

CNC turning is a highly efficient technique for producing cylindrical components from plastic and metal bars or tubes, such as worm shafts. By incorporating live tooling, it becomes possible to achieve simultaneous milling of complex geometries. This combination of capabilities enhances the efficiency and versatility of the CNC turning process.

3.

EDM & Wire-Cut Service

EDM and wire-cut are CNC machining processes that utilize copper, graphite patterns, or molybdenum wire to achieve precise designs with sharp corners, undercuts, and the removal of unnecessary material from workpieces. EDM is extensively employed in rapid tooling and production mold making due to its effectiveness in creating intricate shapes and features.

4.

CNC Grinding Service

If you require a part with an exceptionally flat surface or a round part with tight tolerances of OD and ID within +/- 0.005mm, our CNC grinding machining service is the ideal choice for meeting your production needs. We specialize in providing precise grinding solutions for parts that demand high accuracy and tight tolerances.

5.

CNC Turning Service

Swiss machining offers an efficient method for producing intricate or slender components. By simultaneously moving live tooling and the workpiece, we can consistently cut material that is in close proximity to the workpiece holder. This approach helps prevent deformation, which is a common challenge with traditional CNC lathes.

50+

CNC

MACHINES

ISO

9001:2015

CERTIFIED

10K+

CNC PARTS

MADE MONTHLY

100+

PLASTIC &

METAL MATERIALS

CNC Machined Part Gallery

To provide you with a comprehensive understanding of our CNC machining capabilities, we would like to showcase some of our past projects and demo parts meticulously designed by our skilled engineers. At OYA, we possess the flexibility to handle a wide range of CNC machined parts. Whether your project requires intricate precision or larger-scale production, we are the CNC machining company that can meet your needs. Look no further; your search for a reliable partner ends here!

We Love What We Do

Why Choose Us

TESTIMONIALS

Customer Reviews

They have already used our services

Kristin Watson

5 stars. I am pleased with the communication, which has given me confidence in choosing OYA. The project manager comprehended my requirements and provided solutions to resolve my issues. The project manager's positivity helped me overcome some frustrations I faced. The prototype products were delivered as promised. I am extremely grateful for the personalized service, and I am already a repeat customer.

Ronald Richards

The machining service is outstanding. The parts exhibit exceptional quality, and the communication response time is prompt. I will certainly recommend it to my colleagues if they require CNC machining services.

Wade Warren

My encounter with OYA has been truly remarkable. Right from the beginning, the communication has been precise and swift. They promptly identify any design aspects that may pose production challenges and provide suggested solutions. The pricing for prototyping is competitive, and the quality control of the final product is exceptional. Without a doubt, I will return to them again in the future.

Aviana Plummer

OYA Rapid Prototyping consistently surpasses my expectations. I have been utilizing their services for over 3 years now, and each interaction reinforces how fortunate I am to have discovered them. Having used several overseas machine shops in the past, I can confidently say that OYA outshines them all by a significant margin. Their communication is excellent, they consistently deliver as promised, and the quality of their work is outstanding. While their prices may be slightly higher compared to other options I've used, I firmly believe that the value they provide is well worth it. I have complete confidence in OYA's ability to deliver on their promises, and it is truly a relief to collaborate with them.

Prototype and Production Moldings Made Easy

Get 7-day standard lead times on simple parts between 0.5 in. x 0.5 in. and 4 in. x 3 in.

Upload your part to see if it’s eligible.

1

Upload CAD file

2

Quote & Design Analysis

3

Order Confirmation

4

Parts Shippep

What are the different types of CNC machines?

In a CNC machining shop, there are several types of CNC machines commonly used, including CNC mills, CNC turning machines (or lathes), CNC routers, Electrical Discharge Machining (EDM) machines, and CNC grinding machines.

CNC mills utilize rotating cutting tools that are positioned at different areas of the workpiece to perform cuts. They are versatile and can be used to manufacture a wide range of parts.

CNC lathes, on the other hand, rotate the workpiece against a stationary cutting tool. They are mainly employed for producing cylindrical parts.

Swiss machines are similar to CNC lathes but differ in the movement of cutting tools. Instead of moving the tools, Swiss machines move the workpieces, allowing the production of small diameter round parts without deformation.

CNC routers are similar to CNC mills but generally have less power and are not suitable for cutting the hardest materials. However, they can operate at higher speeds compared to CNC mills.

EDM machines use electrical discharges (sparks) instead of sharp cutting tools to cut material. This process does not involve physical contact between the tool and the workpiece.

CNC machines are often characterized by the number of axes they possess. Machines with more axes can move their tools and/or workpieces in a greater variety of ways, providing enhanced cutting flexibility and the ability to create more complex parts in a shorter timeframe.

How Does CNC Machining Work?

The CNC machining process begins with the use of a computer and CAD (Computer-Aided Design) software, where designers create a part. Subsequently, the programmer utilizes CAM (Computer-Aided Manufacturing) software, such as HyperMill, PowerMill, Maxcam, or UG, to generate tool paths and obtain the NC files required for manufacturing the parts on mills, lathes, or other machines.

The instructions for the CNC machine are transmitted in the form of "G-Code," which the machine can read and execute. Most CNC machines incorporate a worktable and a work holding device to secure the workpiece, which is typically a block of material. Depending on the machine's configuration, the worktable may or may not move.

Once machining commences, the cutting tool comes into contact with the workpiece, removing layers of material. The tool and/or workpiece are moved and/or rapidly rotated based on the instructions in the G-Code. This precise movement ensures that cuts are made in the correct locations until the part is completed.

Advantages of CNC

machining

Here are some of the key advantages of CNC machining compared to other manufacturing processes such as 3D printing, injection molding, urethane casting, laser cutting, plasma cutting, or other sheet metal fabrication processes:

Cost-efficiency:

CNC machining can be cost-efficient for certain types of parts, particularly when the part geometry is simple and requires minimal raw material removal. The high-speed capabilities of CNC machines allow for quick material removal, resulting in lower unit prices compared to 3D printing, which can be time-consuming for such parts.

Precision:

CNC machining offers high precision with machine tolerances typically reaching +/-0.005 mm. This level of precision allows for parts to be machined with tolerances as tight as +/-0.01 mm. In contrast, 3D printing processes, which build parts layer by layer, often have minimum layer heights of 0.05 mm, limiting the achievable tolerances.

Surface finishing:

CNC machining can achieve excellent surface finishes, reducing the need for extensive post-processing. With high spindle speeds and precise cutting tools, CNC machined parts can have surface roughness below Ra 0.8, suitable for bead blasting, painting, or anodizing without manual sanding. In comparison, parts produced through processes like SLS, SLM, or DMLS often have higher surface roughness (Ra > 3.2).

Flexible part sizes:

CNC machining offers flexibility in part sizes. Large CNC machine centers can accommodate tables measuring 6 m x 30 m or larger, enabling the milling of very large parts. Conversely, with precise 5-axis CNC mills and small cutting tools, intricate geometries can be milled from tiny blocks as small as 1 mm x 1 mm x 1 mm. Swiss machines are also suitable for manufacturing small parts for medical applications. Other processes like 3D printing, urethane casting, die casting, and injection molding have limitations in achieving extreme minimum and maximum part sizes.

Overall, CNC machining stands out for its cost-efficiency, precision, surface finishing capabilities, and flexibility in part sizes, making it a preferred choice for various manufacturing applications compared to alternative processes.

CNC Machining Tolerances, Materials & Surface Finishes

Tolerances and Standards

With our extensive selection of CNC mills and lathes, we offer cost-effective CNC machined parts with standard tolerances, as well as high-precision CNC machining for premium products. When partnering with OYA, we ensure that all parts are manufactured precisely according to your specifications. In the absence of 2D drawings, you can provide instructions using ISO 2768 standards.

Machinable Materials

We offer a wide range of industrial-grade CNC machining materials for custom parts, including ABS, POM, PEEK, stainless steel, brass, copper, and more. Whether you need plastic or metal machining, we have the materials to meet your needs.

Surface Finishes

OYA offers a wide variety of high-level surface finishes for CNC machined parts, such as bead blasting, anodizing (Type II, Type III), chrome plating, powder coating, zinc plating, and nickel plating. We provide numerous surface finish options to enhance the appearance and performance of your CNC machined parts.

VERSIONS HAVE EVOLVED OVER THE YEARS

CNC Machining for Various Industrial Applications

Our CNC machining service has received approval from customers worldwide across a range of industries. We have provided CNC machined parts for numerous sectors, including the following and many others.

CNC Machining FAQ's

Upon receiving your Request for Quotation (RFQ), our team of engineers will promptly review the CAD files. They will provide design feedback and optimization suggestions for CNC machining if necessary. Our goal is to ensure the highest quality of CNC machined parts while addressing any factors that may impact the unit price and overall cost. By identifying areas for improvement, we aim to enhance the quality and cost-effectiveness of your CNC machined parts.

OYA operates two CNC machining facilities equipped with over 60 sets of CNC milling and CNC turning machines. With a team of over 40 experienced technical experts, we have the capability to manufacture up to 5000 pieces of various types of CNC machined parts in-house. Additionally, our extensive manufacturing network includes verified partners, allowing us to offer unlimited capacity for additional CNC machined parts.

OYA has established a reputation as one of China’s premier CNC machining companies, renowned for delivering exceptional quality, speed, and customer service. Our state-of-the-art CNC machines enable us to achieve tolerances as tight as +/- 0.02mm, and in some cases, even within +/- 0.01mm. However, it is important to note that achieving such high precision may have an impact on the overall cost of the project.

At OYA, our production engineers thoroughly review each RFQ received from customers to ensure accurate calculation of material and CNC machining costs. We understand that the online CNC machining quotation systems available on most manufacturing platforms may not provide precise estimates. Therefore, our dedicated team carefully evaluates each project to provide customers with reliable and accurate cost calculations.

To ensure optimal results in CNC machining, there are two key considerations to keep in mind. Firstly, it is important to design parts that are CNC machining-friendly. This involves avoiding features such as sharp corners, deep pockets, and thin walls, which can pose challenges in the machining process. Secondly, selecting the right CNC machining company for your specific project is crucial. For simple and small parts, it is often more cost-effective to work with smaller CNC machine shops. However, for precision parts with complex geometries, partnering with a CNC machining company like OYA, equipped with precision multi-axis CNC mills, lathes, and comprehensive inspection facilities, would be a better fit.

Based on our past CNC machining orders, more than 90% of them have been completed within approximately 7 days. Simple CNC machined parts can typically be finished within 2 days, while complex or large CNC machined parts may require 15 days or more. It is important to consider the quantity of parts needed as well. Additionally, through our extensive CNC machining manufacturing networks, we can also utilize CNC machining shops located near your location in the US and Europe, reducing shipping time and improving overall efficiency.

OUR ARTICLES

Related Resources

The Fundamentals of Plastic Extrusion: Process, Materials, and Applications

Plastic extrusion is a widely used manufacturing process for shaping plastics,...

How does sheet metal fabrication work?

Because thin sheets of metal are more malleable than a thick workpiece, they c...