Our Advantages of Mold Making Services

OYA is an experienced provider of mold making services with lots to offer beyond our competitors:

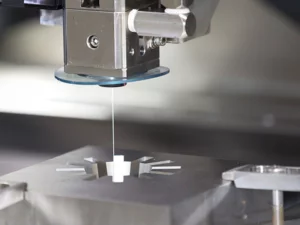

1. 1. Fast DFM reports

We assess design feasibility during quoting and deliver a thorough DFM (Design for Manufacturability) report prior to production, addressing any potential manufacturing issues.

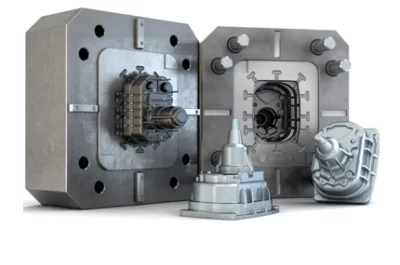

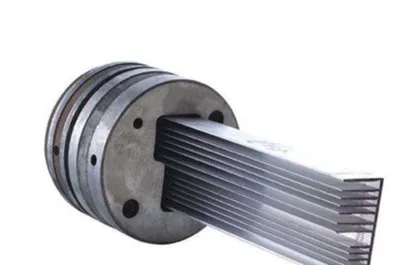

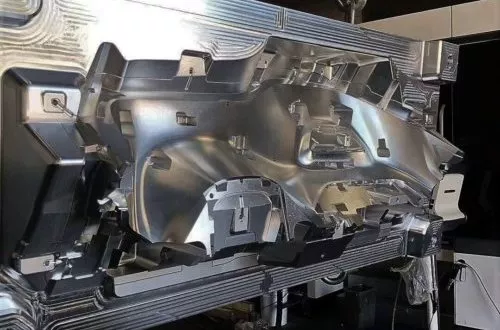

2. Wide range of molds

We offer several different types of molds, which means you can avoid splitting your projects; just send everything to us to ensure your project runs smoothly.

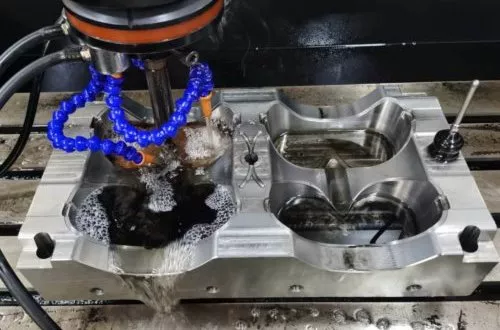

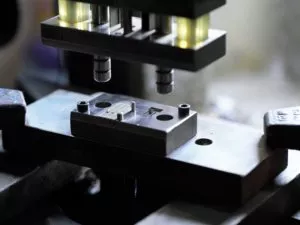

3. Fast Turnaround

Our large facility and machining capabilities allow us to build molds quickly, whatever the application or material, which means you can get your moldings completed faster.

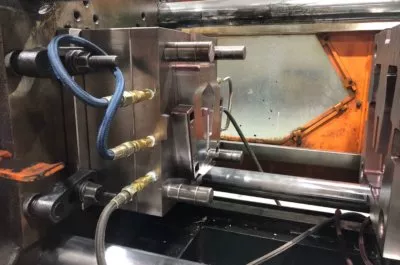

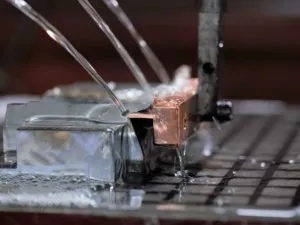

4. Molding Capabilities

OYA can ship your molds to you directly, but we can also handle injection molding and other production services to deliver you prototypes and final parts using those molds.